Mail us on contact@eplgroup.co.in

Call us on +91 22 69037777

MODULAR FURNITURE

Educational & Healthcare

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard make a type specimen book. It has survived not only.

1. Single Beds (900mm high x 900mm wide x 1800mm deep)

2. Double Beds (900mm high x 1600mm wide x 1800mm deep)

These have a headboard and a footboard made from 18mm thick Pre laminated boards suitably contoured.

The side panels and mattress panels are made from 18mmm thick pre-laminated particle boards.

The beds have an internal concealed framework made from M.S. square pipes of 18gauge thickness and having a section size of 30mm x 30mm

All beds shall conform to the following sections of ANSI / BIFMA X5.5-2008 - Tests for Desks & Table Products;

- Stability under vertical load - Sec'n 4.3

General Specifications :

All powder coated surfaces will have a dry film thickness of minimum 50 microns. The shall also conform to the following specifications of IS 13871: 1993;

- Pencil Hardness Test as specified in Sec’n 1 of Part V of IS 101: 1998

- Scratch Hardness Test as specified in Sec’n 2 of Part V of IS 101: 1998

- Flexibility Test as specified in Sec’n 2 of Part V of IS 101: 1998

- Cross-cut Adhesion Test as specified in Sec’n 2 of Part V of IS 101: 1998

- Impact Resistance Test as specified in Sec’n 2 of Part V of IS 101: 1998

All pre-laminated particle boards shall also conform to the following specifications of IS 12823: 1990; Reaffirmed 2005

- Density and moisture content tested as per Part III of IS 2380:1977

- Modulus of elasticity & rupture in bending tested as per Part IV of IS 2380:1977

- Tensile strength perpendicular to the surface tested as per Part V of IS 2380:1977

- Screw withdrawal strength tested as per Part XIV of IS 2380:1977

- Water absorption tested as per Part XVI of IS 2380:1977

- Swelling in water tested as per Part XVII of IS 2380:1977

- Resistance to surface abrasion tested as per Clause 10.10 of Annexure B

- Resistance to steam tested as per Clause 10.10 of Annexure C

- Resistance to cracking of lamination under heat as per Clause 10.10 of Annexure D

- Resistance to cigarette burns as per Clause 10.10 of Annexure E

- Resistance to stains as per Clause 10.10 of Annexure F

Hinged Door Units (Bulk Storage Units/Ward robes)

The entire unit must be made from 18mm thick pre laminated particleboard, except back, which is made from 9mm thick pre-laminated particleboard.

These units must have hinged door shutters having spring-loaded auto-closing hinges. All units have a multi purpose type lock and are provided with Stainless steel handles of matt finish.

All units must be provided with plastic headed leveling bolts of M6 size to take care of any variations in the floor level.

These units must be entirely factory made and delivered to site in a knocked down condition where they must assembled by means of standard knock down type fittings.

All units shall conform to the following sections of ANSI / BIFMA X5.9-2004 - Tests for Storage Units;

- Force test for door locks - Sec'n - 14.3

- Strength test for hinged doors - Sec'n - 17.2

- Hinge over-ride test for hinged doors - Sec'n - 17.3

- Wear & Fatigue test for hinged doors - Sec'n - 17.6

- open and close test for hinged doors - Sec'n - 17.11

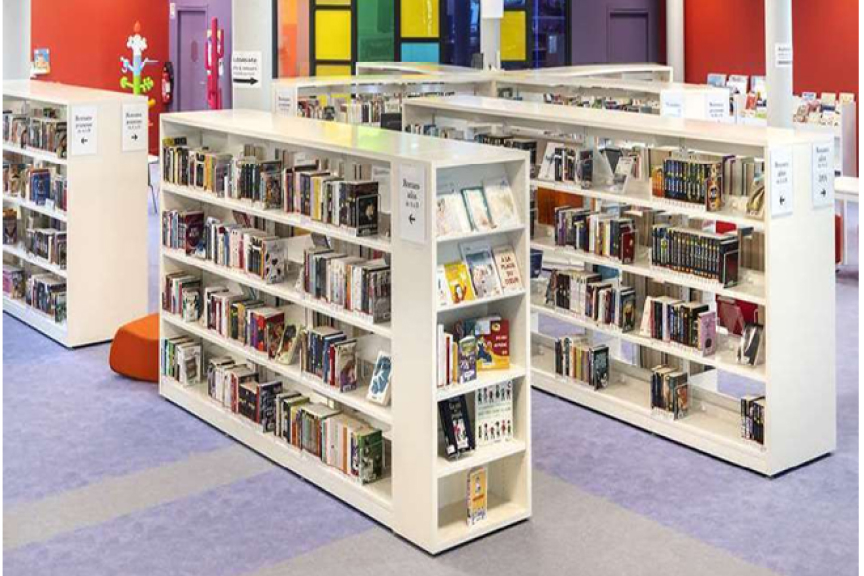

These shall comprise of single faced fixed, single faced mobile and double faced mobile units. Each unit will comprise of 3 units located side-by-side

The movement shall be on round bars of 25mm diameter which must be secured to the ground.

The under carriage shall be made from minimum 2.0 mm thick hot rolled steel sheets.

Each base will have a minimum of 4 wheels with free movement.

The superstructure must be of the knock-down design with the sides made from minimum 1.0mm thick CRCA steel and the backs from minimum 0.8mm thick CRCA steel.

Each unit must have a set of lockable shutters at the end. A minimum of 5 shelves made from at least 0.8mm thick CRCA steel shall be provided in each unit.

The shelves must be of the boltless type for easy adjustability.

The drive mechanism must be of the chain type with suitable reduction to provide effortless movement and operated by a wheel or 3-pronged handle of a convenient dimension.

A central locking device must be provided in the last mobile unit

All metal components will be duly powder coated.

1. Single Beds (900mm high x 900mm wide x 1800mm deep)

2. Double Beds (900mm high x 1600mm wide x 1800mm deep)

These have a headboard and a footboard made from 18mm thick Pre laminated boards suitably contoured.

The side panels and mattress panels are made from 18mmm thick pre-laminated particle boards.

The beds have an internal concealed framework made from M.S. square pipes of 18gauge thickness and having a section size of 30mm x 30mm

All beds shall conform to the following sections of ANSI / BIFMA X5.5-2008 - Tests for Desks & Table Products;

- Stability under vertical load - Sec'n 4.3

Our Projects

Project Gallery

OUR CERTIFICATIONS

Our Clients